Fiberglass Composite Material is used to form any kind of fiberglass products. Fiberglass Composite Material can produce the highest strength to weight ratio known to man. The end product of fiberglass is corrosion resistant – provide long term resistance to severe chemical and temperature environments. With fiberglass, you can have design flexibility – it can be molded into complex shapes at relatively low coast.

Perdana Chemindo Perkasa offers comprehensive Fiberglass Composite Material products with a so many variety and options to choose from. Please consult to our customer relation staff for better product understanding.

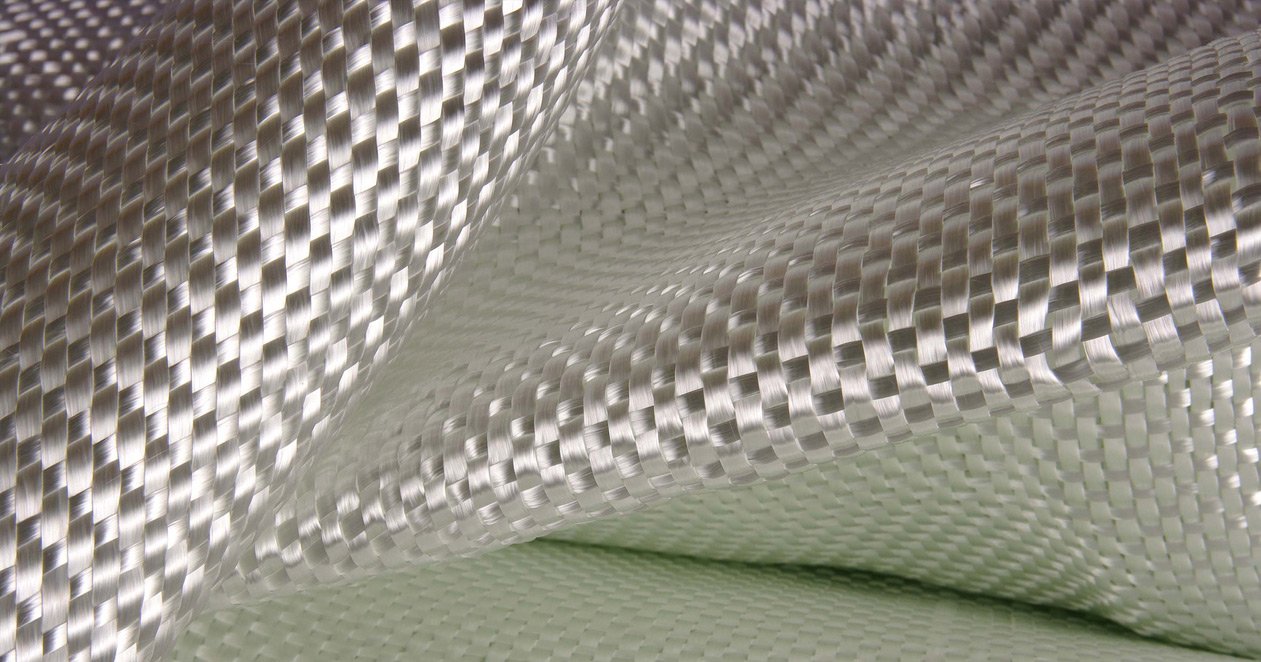

| Fiberglass Composite Material |

Details |

Packings |

| E-Glass Chopped Strand Mat (CSM) / Fiberglass Mat Taishan Fiber CTG |

|

30 kgs & 54 kgs |

| E-Glass Chopped Strand Mat (CSM) / Fiberglass Mat JUSHI |

|

30 kgs & 54 kgs |

| CHEMPOGLASS E-Glass Woven Roving (EWR) |

|

40 kgs |

| CHEMPOGLASS Fiberglass AR mesh |

|

50m/roll |

| Chempocore Honeycomb PP |

|

- |

| Chempocore polyurethane (PU) foam sheet |

|

- |

| Polyurethane (PU) rigid foam liquid A+B |

|

225kgs part A & 250kgs part B |

| Miracle gloss mold release agent |

|

311 gr |

| Wacker HDK n20 / aerosil |

|

10 kgs |

| CHEMPOFILL Talc powder Liaoning / Haichen |

|

25 kgs |

| CHEMPOGLOW strontium glow in the dark powder / phosporecent pigment MT & MH series |

|

10gr, 25gr, 100gr, 250gr, 500gr, 1kg |

| CHEMPOGLASS Chopped strand Mat (CSM) / Fiberglass Mat 30kg & 54 kg |

|

- |

| CHEMPOGLASS fiberglass cloth 4oz / surfboard fabric |

|

- |